Since its inception, HTS-110 has been at the forefront of global innovation in applied HTS products.

HTS-110 was formed in 2004 with the aim of commercialising almost two decades of pioneering HTS R&D by Industrial Research Limited (IRL), a former New Zealand Crown Research Institute, and its predecessor the Department of Scientific and Industrial Research (DSIR). HTS-110 became part of NZX-listed Scott Technology in 2011 and a decade later has become an independent company once again.

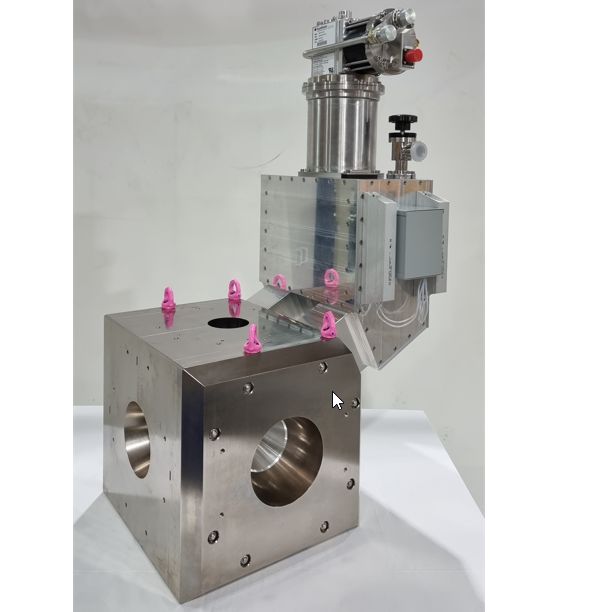

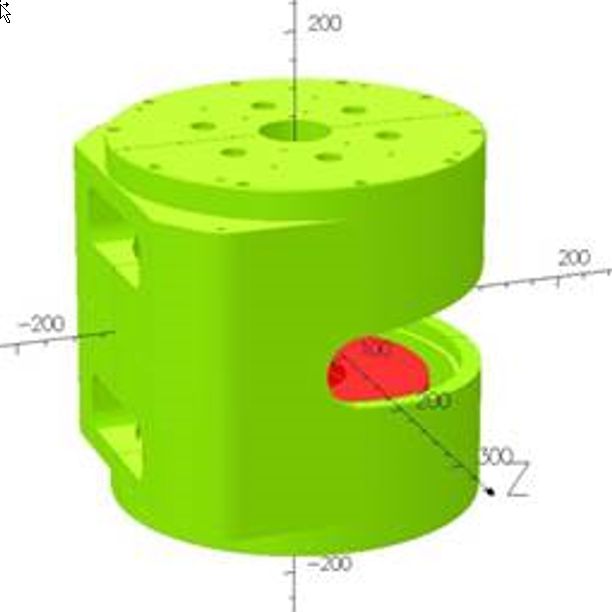

HTS-110 has accumulated extensive experience in providing innovative magnetic solutions including x-ray and neutron beamline sample environments, high-throughput magnets for materials analysis, compact magnets for magneto-optical studies and high uniformity magnets for magnetic resonance and beamline instrumentation. In addition, a large range of custom magnetic solutions have been provided for specific applications ranging from energy storage to mine-sweeping.

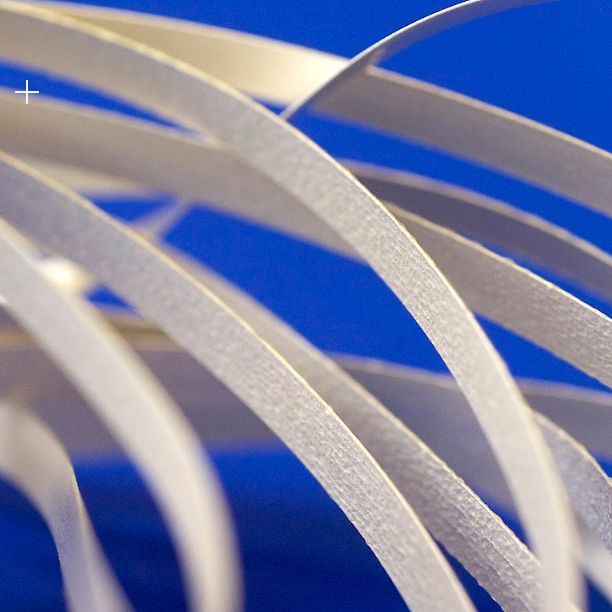

HTS-110 remains the only company in the world specialising in HTS magnet systems and components. Components include the trusted CryoSaver™ current leads and CryoForge coils. Our unique expertise derives from more than a century of accumulated HTS experience across the current team. Operating from its facility in Lower Hutt, New Zealand, HTS-110 maintains a strong relationship with its parent HTS research team, now known as the Robinson Research Institute of Victoria University of Wellington.