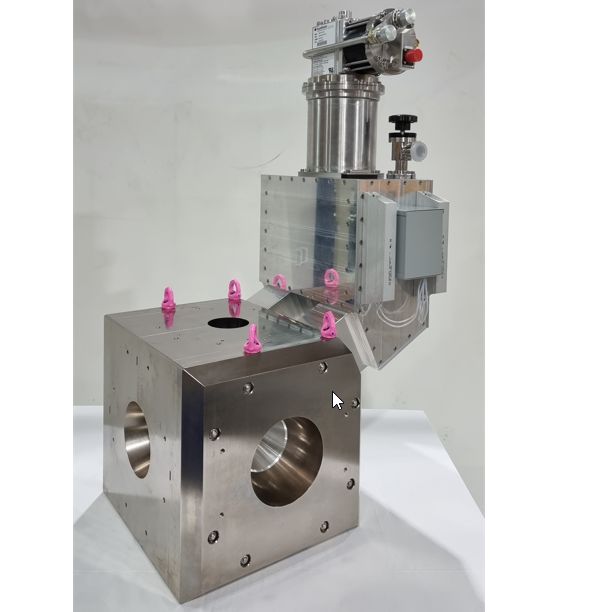

We are excited to announce we have shipped our highest field magnet to date, an HTS-110 12 tesla split-coil system to be used as a research tool in the measurement of current carrying capacities of the high-transition temperature superconducting wires.

This magnet represents a significant extension in available field range for this tool which until now had been offered with 5 and 8 tesla field strengths, and it also represents a step up in field strength from any magnet produced in the past. HTS-110’s previous record for a commercial magnet was 9.4 T in a high-uniformity solenoid, designed in that case for chemical analysis using nuclear magnetic resonance spectroscopy.

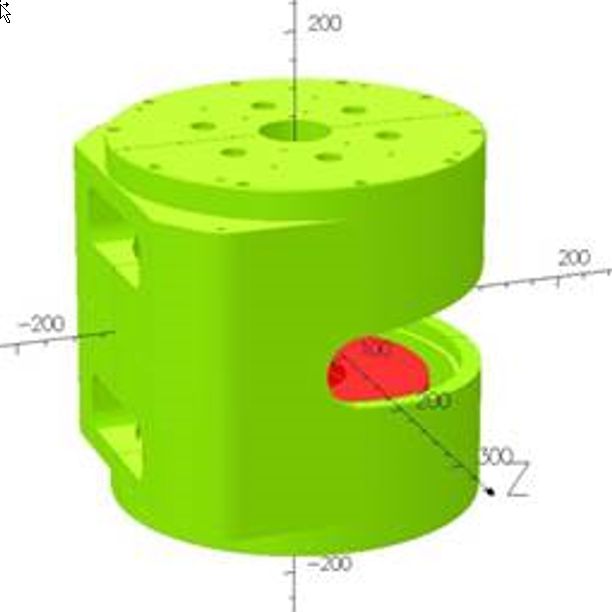

Production and successful testing of the new magnet followed a focused electromagnetic and mechanical design process to establish the basic operational parameters for the HTS coil system required, namely the required number of turns in the HTS coil packs and their maximum allowable operating current and temperature. For higher-field magnets a mounting concern then becomes the management of forces within and between these superconducting coil packs, where a large amount of energy is stored; careful balancing of the engineering parameters is required, taking into consideration the strength of the HTS wire itself.

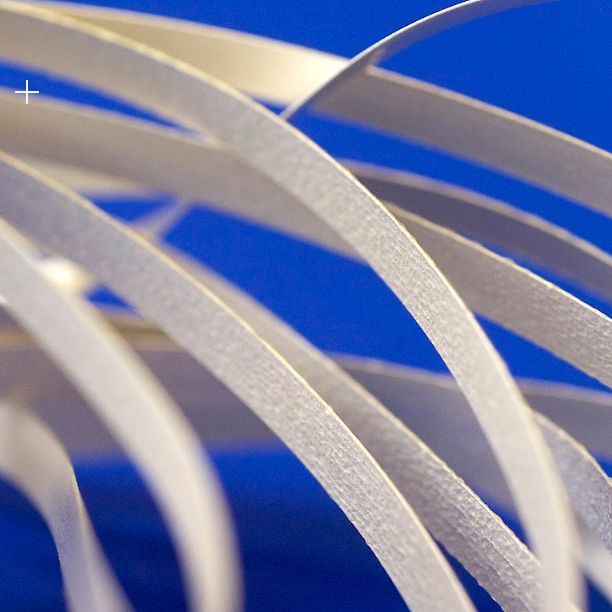

In the present case the wire employed was so-called first-generation HTS conductor (formulated with a Bi-Sr-Ca-Cu-O compound in a silver matrix) laminated with stainless steel for strength. This wire, after testing, was wound into pancake-like modules, which were then assembled as two stacks for the split pair magnetic design. Once integrated into the cryostat with associated cooling system, the magnet was cooled and energised to full field at an operating current of just over 220 A. These first tests of a new magnet system can be nerve-wracking but this magnet passed with flying colours, proving stable in both ramping and in full-field soak tests. The magnet thus provides an excellent foundation for the “SuperCurrent” measurement instrumentation developed and integrated by our partners in Robinson Research Institute of the Victoria University of Wellington, for an end-customer in the United States.

Back to all News